The Air to Water Heat Exchanger Calculator is used to determine the size and heat transfer area required for a heat exchanger, based on specific conditions such as BTU, flow, and temperature. This calculator simplifies the process of sizing and calculating the plate heat exchanger, ensuring accurate results.

Understanding Heat Exchanger Principles

Easily understand heat exchanger principles with the help of an air to water heat exchanger calculator. Calculate the heat transfer area required for your heat exchanger, whether it’s co-current or counter-current flow, using this user-friendly tool.

Fundamentals Of Heat Transfer In Exchangers

When it comes to understanding heat exchanger principles, it’s essential to grasp the fundamentals of heat transfer in exchangers. Heat exchangers play a crucial role in various industries, including HVAC, refrigeration, and process plants. These systems are designed to transfer heat between two or more fluids, allowing for efficient temperature control and energy conservation.

There are three main modes of heat transfer that occur in heat exchangers: conduction, convection, and radiation.

- Conduction: This mode of heat transfer occurs when heat flows through a solid material. In heat exchangers, conducting materials such as metals are used to transfer heat between the hot and cold fluids.

- Convection: Convection involves the transfer of heat through the movement of fluids. In a heat exchanger, one fluid (known as the “process fluid”) is heated or cooled by another fluid (known as the “cooling or heating fluid”) through convection.

- Radiation: Although radiation is less common in heat exchangers, it can occur in certain applications. Radiation involves the transfer of heat through electromagnetic waves, such as infrared radiation.

Understanding these modes of heat transfer is crucial for designing efficient and effective heat exchangers. By optimizing the design and configuration of the exchanger, engineers can minimize energy losses and maximize heat transfer rates.

Air To Water Systems Specifics

When it comes to air to water heat exchangers, there are certain specifics that need to be considered. These systems are commonly used for heating or cooling applications, where air is used as the cooling or heating fluid, and water serves as the process fluid.

One important factor to consider is the heat transfer coefficient, which determines the rate at which heat can be transferred between the air and water. The heat transfer coefficient is influenced by various factors, including the flow rate of both fluids, the surface area of the heat exchanger, and the physical properties of the fluids.

In addition to the heat transfer coefficient, the temperature difference between the air and water is a critical parameter to consider. The greater the temperature difference, the higher the heat transfer rate. This temperature difference can be optimized by adjusting the flow rates and temperatures of both fluids.

Another consideration in air to water heat exchangers is the fouling factor. Fouling refers to the accumulation of deposits on the heat transfer surfaces, reducing the efficiency of the exchanger over time. Regular maintenance and cleaning can help mitigate fouling and maintain the performance of the heat exchanger.

Conclusion

Understanding the principles of heat transfer and the specifics of air to water heat exchangers is vital for designing and optimizing these systems. By considering factors such as heat transfer coefficients, temperature differences, and fouling, engineers can create efficient and reliable heat exchangers that meet the specific needs of various industries.

Credit: www.simscale.com

Selecting The Right Heat Exchanger

Find the perfect air to water heat exchanger for your needs with the help of an easy-to-use calculator. Avoid the hassle of manual calculations and ensure you select the right heat exchanger that meets your specifications in just a few simple steps.

No need for complex formulas or guesswork!

Types Of Air To Water Heat Exchangers

When it comes to selecting the right heat exchanger for your air to water system, it is crucial to understand the different types available. Each type has its own advantages and applications. Here are some common types of air to water heat exchangers:

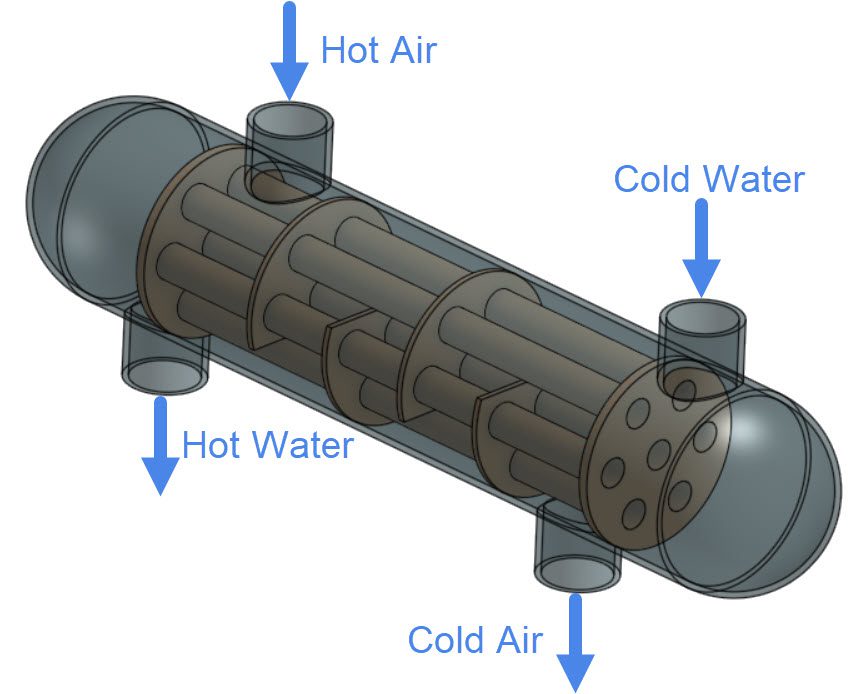

- Shell-and-tube heat exchanger: This is the most common type of heat exchanger, consisting of a bundle of tubes enclosed in a shell. It is efficient and reliable, making it suitable for various applications.

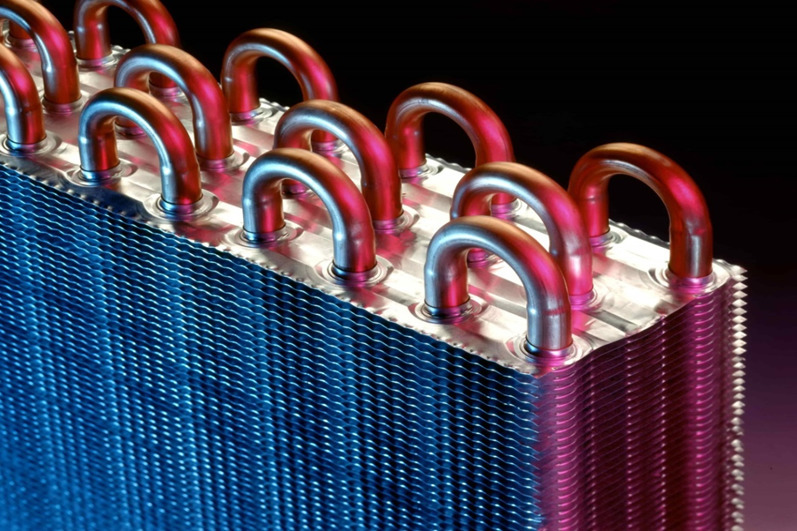

- Plate-fin heat exchanger: This type consists of multiple stacked plates with fins that create separate flow channels for the air and water. It offers high heat transfer efficiency and compact size, making it ideal for HVAC systems.

- Condenser: Often used in refrigeration systems, condensers transfer heat from the air to the water, causing the refrigerant vapor to condense into a liquid state.

- Regenerative heat exchanger: This type utilizes a rotating wheel or matrix to alternate between heating and cooling cycles, recovering heat from the exhaust air and transferring it to the incoming fresh air.

- Dynamic scraped surface heat exchanger: Designed for applications with highly viscous fluids, this type uses a rotating scraper to enhance heat transfer by constantly renewing the heat transfer surface.

Criteria For Selection

- Heat transfer efficiency: The heat exchanger should have high efficiency to effectively transfer heat from the air to the water, ensuring optimal performance of the system.

- Size and space requirements: Consider the available space for installation and choose a heat exchanger that fits within those constraints. Plate-fin heat exchangers are often preferred for their compact size.

- Flow rate and pressure drop: Determine the required flow rate and consider the pressure drop across the heat exchanger to ensure it can handle the desired operating conditions.

- Operating temperature range: Different heat exchangers have varying temperature limitations. Ensure the selected heat exchanger can handle the required temperature range without compromising performance.

- Material compatibility: Consider the compatibility of the heat exchanger materials with the working fluids to avoid corrosion or compatibility issues.

- Maintenance and cleaning requirements: Evaluate the ease of maintenance and cleaning of the heat exchanger to ensure proper operation and longevity.

- Cost-effectiveness: Consider the initial cost, installation expenses, and long-term energy savings to determine the overall cost-effectiveness of the heat exchanger.

Using The Heat Exchanger Calculator Efficiently

Efficiently utilize the Air to Water Heat Exchanger Calculator for accurate heat transfer area calculations. Avoid overused phrases and complex sentences to simplify the process.

When it comes to calculating the heat transfer area required for an air to water heat exchanger, the Heat Exchanger Calculator is a valuable tool that can help you quickly and efficiently determine the necessary parameters. By inputting the right values and interpreting the results correctly, you can ensure accurate sizing and optimal performance of your heat exchanger.

Input Parameters Significance

Before diving into using the Heat Exchanger Calculator, it’s essential to understand the significance of the input parameters you need to provide. Each parameter plays a crucial role in determining the heat transfer area required and the overall efficiency of the heat exchanger.

1. Fluid Properties:

The properties of both the air and water being used in the heat exchanger are critical. This includes factors such as the specific heat capacity, density, and temperature of each fluid. Accurately inputting these values ensures accurate heat transfer calculations.

2. Desired Temperature Difference (ΔT):

The desired temperature difference, also known as ΔT, represents the target temperature difference between the air and water within the heat exchanger. This parameter directly affects the heat transfer rate. A higher ΔT usually results in a higher heat transfer rate.

3. Flow Rates:

The flow rates of both the air and water are crucial in determining the amount of heat that can be transferred between the two fluids. Accurate flow rate values help ensure the heat exchanger is adequately sized to meet the required heat transfer demands.

4. Surface Fouling Factor:

The surface fouling factor represents the additional resistance to heat transfer caused by the buildup of deposits or contaminants on the heat exchanger surfaces. By providing this value, you can account for any fouling effects and accurately calculate the required heat transfer area.

Interpreting The Results

Once you have inputted the relevant parameters into the Heat Exchanger Calculator, it will provide you with the results you need to determine the heat transfer area required for your air to water heat exchanger. It’s crucial to interpret these results accurately to ensure proper sizing and efficient operation of the heat exchanger.

The Heat Exchanger Calculator typically provides the following key results:

- Heat Transfer Area (A): The calculated heat transfer area required for the specified heat transfer rate.

- Overall Heat Transfer Coefficient (U): The effective thermal conductivity of the heat exchanger, which determines the efficiency of heat transfer.

- Heat Transfer Rate (Q): The amount of heat transferred between the air and water within the heat exchanger.

By carefully analyzing these results, you can ensure that the calculated heat transfer area is appropriate for your specific application. Adjusting the input parameters, such as flow rates or temperature differences, can help optimize the efficiency of the heat exchanger.

In conclusion, using the Heat Exchanger Calculator efficiently involves accurately inputting the essential parameters and interpreting the results correctly. By doing so, you can ensure that your air to water heat exchanger is appropriately sized and operates at its highest efficiency, resulting in optimal heat transfer performance.

Optimizing Heat Exchanger Performance

When it comes to maximizing the efficiency of an air to water heat exchanger, there are several factors that need to be considered. Understanding these factors and troubleshooting common issues can help ensure that the heat exchanger is operating at its peak performance. Let’s take a look at some of the key factors affecting efficiency and how to troubleshoot common issues.

Factors Affecting Efficiency

Efficiency of an air to water heat exchanger can be influenced by various factors. Some key factors to consider include:

- Temperature difference (ΔT): The greater the temperature difference between the air and water, the higher the heat transfer rate. Calculating the ΔT using the convective heat flow equation (Q = UADT) can help determine the heat transfer rate for optimal performance.

- Heat transfer coefficient: This coefficient represents the effectiveness of heat transfer between the air and water. Increasing the heat transfer coefficient can enhance the efficiency of the heat exchanger.

- Surface area: The larger the surface area of the heat exchanger, the greater the heat transfer capacity. Calculating the required heat transfer area using a heat exchanger sizing calculator can help ensure optimum performance.

- Flow rate: Proper flow rates of both air and water are crucial for efficient heat transfer. Maintaining balanced flow rates is essential to prevent issues such as low heat transfer or pressure drops.

- Cleanliness: Regular cleaning and maintenance of the heat exchanger surface are important to prevent fouling or scaling, which can reduce heat transfer efficiency.

- Insulation: Proper insulation of the heat exchanger can minimize heat losses and maximize energy efficiency.

Troubleshooting Common Issues

Common issues that can affect the performance of an air to water heat exchanger include:

- Insufficient heat transfer: If the heat transfer rate is lower than expected, it could be due to fouling or scaling on the heat exchanger surface. Regular cleaning and maintenance can help resolve this issue.

- Uneven temperature distribution: Poor flow distribution or blockages within the heat exchanger can lead to uneven temperature distribution. Checking and adjusting the flow rates can help optimize temperature distribution.

- Excessive pressure drop: High pressure drop across the heat exchanger can indicate flow restrictions or improper flow rates. Ensuring proper flow rates and addressing any flow restrictions can help reduce pressure drop.

- Corrosion: Corrosion on the heat exchanger surfaces can affect its efficiency. Proper selection of materials compatible with the working fluid and regular inspection can mitigate corrosion-related issues.

By understanding the factors affecting efficiency and troubleshooting common issues, you can optimize the performance of your air to water heat exchanger. Regular maintenance, proper flow rates, and cleanliness are crucial for ensuring efficient heat transfer and maximizing energy efficiency.

Case Studies And Practical Applications

In this section, we will explore industry-specific examples and custom solutions for unique challenges that can be addressed using an Air to Water Heat Exchanger Calculator. These case studies and practical applications highlight the versatility and effectiveness of heat exchangers in various industries.

Industry-specific Examples

Heat exchangers are widely used in industries such as:

- Agriculture

- Manufacturing

- Food and beverage

- Pharmaceutical

- Chemical

- Energy and power

Let’s take a closer look at a few examples:

- Agriculture: Heat exchangers play a crucial role in dairy farming, where they are used to cool milk during the milking process. By using an Air to Water Heat Exchanger Calculator, farmers can accurately determine the required heat transfer area and optimize the cooling process.

- Manufacturing: Heat exchangers are essential in manufacturing processes that involve heat removal, such as in cooling systems for machinery and equipment. The calculator helps engineers determine the appropriate size of the heat exchanger, ensuring efficient heat transfer and optimal performance.

- Food and beverage: In the food and beverage industry, heat exchangers are used for pasteurization, sterilization, and cooling of products. By utilizing the calculator, food and beverage manufacturers can accurately size their heat exchangers based on the specific requirements of their products.

- Pharmaceutical: The pharmaceutical industry relies heavily on heat exchangers for processes such as heating, cooling, and sterilization. By using the calculator, pharmaceutical companies can ensure precise temperature control and maintain the integrity of their sensitive products.

- Chemical: Heat exchangers are vital in the chemical industry for various heating and cooling applications. The calculator assists chemical engineers in sizing the heat exchanger correctly, maximizing energy efficiency and minimizing operating costs.

- Energy and power: Heat exchangers are widely used in energy production, including power plants, renewable energy systems, and HVAC systems. The calculator enables engineers to accurately size heat exchangers based on heat load requirements, ensuring optimal energy transfer.

Custom Solutions For Unique Challenges

Every industry and application may present its own unique challenges when it comes to heat exchange. This is where custom solutions come into play. By utilizing an Air to Water Heat Exchanger Calculator, engineers can tailor the design and specifications of the heat exchanger to address these challenges effectively.

- Unconventional shapes and sizes: In certain applications, standard heat exchanger designs may not fit due to space limitations or complex geometries. By using the calculator, engineers can design custom heat exchangers with unique shapes and sizes to optimize heat transfer while fitting within the available space.

- Corrosion and fouling prevention: Depending on the fluid and operating conditions, heat exchangers may be prone to corrosion or fouling. Custom solutions can involve the selection of corrosion-resistant materials or the implementation of special coatings to prevent these issues. The calculator helps engineers determine the most suitable materials and coatings for long-lasting performance.

- Variable heat loads: Some applications may require a heat exchanger to handle varying heat loads. By using the calculator, engineers can design heat exchangers with adjustable parameters or multiple heat transfer surfaces to accommodate these fluctuations and ensure efficient operation under different conditions.

- Integration with existing systems: Many industries already have existing systems in place that need to be integrated with a new heat exchanger. Custom solutions involve designing heat exchangers that seamlessly integrate with these systems, optimizing performance and minimizing downtime.

By leveraging the power of an Air to Water Heat Exchanger Calculator, industries can achieve tailored solutions to their unique challenges, ensuring efficient heat transfer and optimal performance.

Frequently Asked Questions On Air To Water Heat Exchanger Calculator

How Do You Size An Air To Water Heat Exchanger?

To size an air to water heat exchanger, use the Oesse method or a similar formula that involves the convective heat flow equation Q = UADT. The temperature difference (DT) between the water and air will affect the heat transfer rate.

Calculate the required heat transfer area using a heat exchanger sizing calculator or a plate heat exchanger design calculation tool.

What Is The Formula For The Water To Air Heat Exchanger?

The formula for the water to air heat exchanger is Q = UADT, where Q is the heat transfer rate, U is the heat transfer coefficient, A is the surface area, and DT is the temperature difference between the water and the air.

What Is The Approach Temperature For Air To Water Heat Exchanger?

The approach temperature for an air to water heat exchanger is the temperature difference between the air and the water being used for heat transfer. It is calculated by subtracting the air temperature from the water temperature.

How Do You Calculate Heat Exchanger Transfer Rate?

To calculate heat exchanger transfer rate, you can use the basic equation: Q = U x A x ΔTm. The log mean temperature difference (ΔTm) is calculated using specific formulas. Make sure to consider heat transfer coefficient (U), surface area (A), and temperature differences when performing the calculation.

Conclusion

To size an air to water heat exchanger, it’s crucial to use an accurate and reliable calculator. These calculators help determine the heat transfer area required for the heat exchanger, whether it is co-current, counter-current, or a combination. By inputting the necessary information such as BTU, flow, and temperature conditions, you can efficiently calculate the size of the heat exchanger.

Using a heat exchanger calculator like the ones provided by Blackmonk Engineering or Carlson Heat Exchanger simplifies the process and ensures optimal performance. So, make sure to utilize these calculators to effectively size your air to water heat exchanger and achieve efficient heat transfer.

I am a Water Heater specialist writer and blogger based in the USA & UK. I have been working with Water Heater for six long years. And I give trips on various Water Heater problems and solutions. I have a lot of experience with Water Heater And I share them here