Water to air heat exchanger installation in Austin, Texas, United States is a simple and easy process. With the proper tools and measurements, the heat exchanger can be installed in the plenum of a forced air furnace, ensuring efficient heating and cooling throughout the home.

By attaching the brackets to the plenum and connecting the heat exchanger using SharkBite fittings and PEX, homeowners can achieve optimal performance from their heating system. Wiring the Aquastat and following the provided wiring diagram ensures seamless operation when the house is occupied.

With careful consideration of the heat exchanger’s location and size, homeowners can enjoy the benefits of an efficient and reliable water to air heat exchanger.

Assessing Your Heating Requirements

When it comes to water to air heat exchanger installation, it is crucial to assess your heating requirements accurately. This involves considering factors such as determining the capacity needed and understanding the layout of the current system. By carefully evaluating these aspects, you can ensure that the installation process goes smoothly and that your heating needs are met efficiently.

Determining The Capacity Needed

Determining the capacity needed is an essential step in the water to air heat exchanger installation process. This involves assessing the size of your space and calculating the heating load required to maintain a comfortable temperature. To determine the capacity needed, you can use the following formula:

Heating Load (BTU/hr) = Square Footage of Space × Heat Loss Factor

The heat loss factor takes into account various factors such as insulation, climate, and windows. It is typically measured in BTU/hr per square foot. By accurately calculating the heating load, you can choose a heat exchanger with the appropriate capacity to meet your heating needs.

Understanding The Layout Of The Current System

Understanding the layout of the current heating system is crucial for a successful water to air heat exchanger installation. This involves identifying the location of the heating coil and the hot air furnace plenum. By familiarizing yourself with the current system layout, you can determine the best position for installing the heat exchanger.

To gain a better understanding of the system layout, you can simulate the plenum and analyze the airflows within it. This will help you identify any potential obstacles or limitations that may affect the placement of the heat exchanger. Additionally, you can also consider mounting the heat exchanger on the return line if it proves to be a more feasible option.

Another aspect to consider is adjusting the fan speed to optimize the performance of the heat exchanger. By adjusting the fan speed, you can ensure proper airflow and enhance the heat transfer process. Consult the manufacturer’s recommendations or seek professional advice to determine the ideal fan speed for your specific installation.

In conclusion, assessing your heating requirements is a critical step in the water to air heat exchanger installation process. By accurately determining the capacity needed and understanding the layout of the current system, you can ensure a successful and efficient installation. This will result in an optimized heating system that meets your comfort needs while maximizing energy efficiency.

Choosing The Right Exchanger

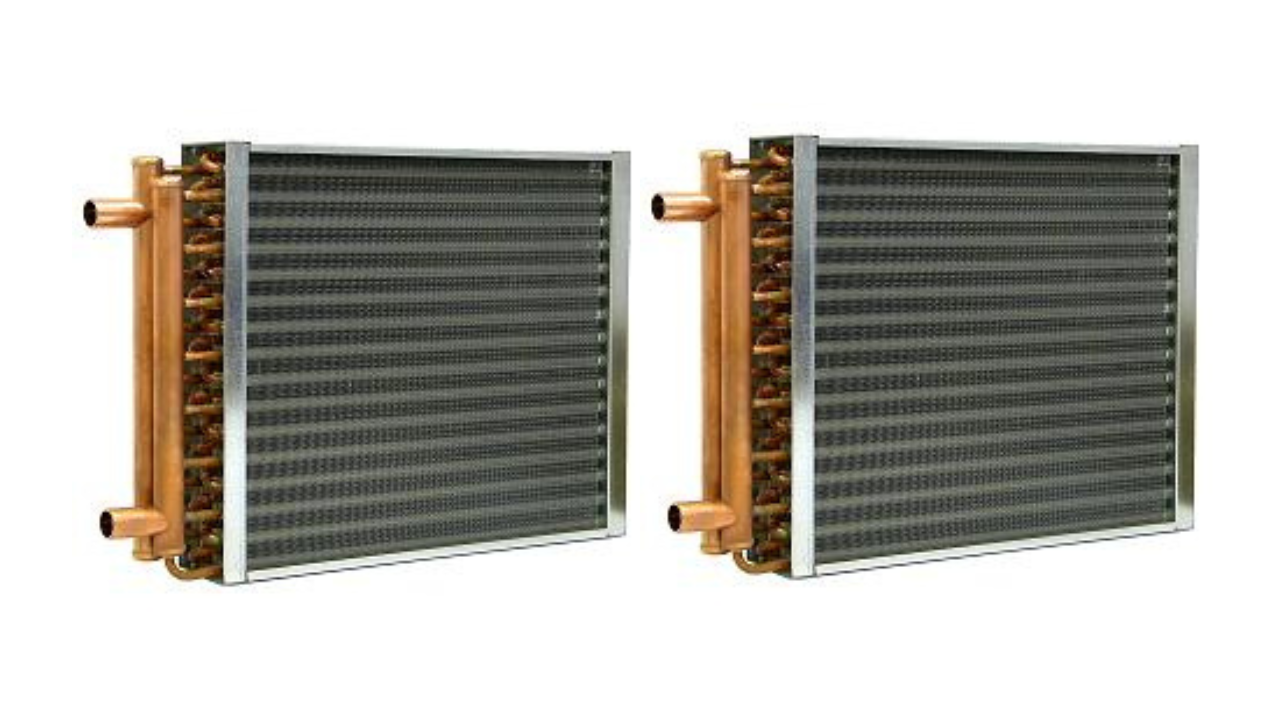

When it comes to water to air heat exchanger installation, choosing the right exchanger is crucial for optimal heating and cooling performance. The right exchanger should be compatible with your existing system, appropriately sized, and efficient. Let’s dive into each of these considerations in detail.

Compatibility With Existing Systems

Before selecting a heat exchanger, it’s crucial to ensure compatibility with your existing heating and cooling systems. Different systems have different requirements, so it’s essential to choose an exchanger that can seamlessly integrate into your setup.

Sizing And Efficiency Considerations

Proper sizing of the heat exchanger is vital to ensure efficient operation. An undersized exchanger may struggle to meet your heating and cooling demands, leading to reduced performance. On the other hand, an oversized exchanger may lead to energy wastage.

Efficiency is another critical aspect to consider when choosing a water to air heat exchanger. Look for models with high heat transfer efficiency to maximize energy savings and reduce operating costs. Additionally, consider the physical space available for installation, as some exchangers may require more space than others.

To determine the ideal size and efficiency requirements for your system, consult with a professional HVAC technician. They will assess your specific needs and recommend the most suitable exchanger for your setup.

Installation Considerations

During the selection process, also consider the ease of installation. Look for exchangers that come with clear installation instructions and require minimal modifications to your existing system. This will help ensure a smooth installation process and minimize any potential disruptions.

Additionally, check if the exchanger comes with necessary brackets or mounting hardware. Having the right tools available beforehand will save you time and effort during the installation.

Maintenance And Durability

Lastly, consider the maintenance requirements and durability of the heat exchanger. Opt for models that are easy to clean and maintain to ensure long-term efficiency. Look for exchangers made from high-quality materials that can withstand the demands of regular usage without deterioration.

In conclusion, choosing the right water to air heat exchanger is crucial for a successful installation. Consider compatibility with your existing systems, proper sizing and efficiency, ease of installation, and maintenance requirements to ensure optimal performance and longevity of your heat exchanger.

Preparing For Installation

Installing a water to air heat exchanger is made easy with these step-by-step instructions. From measuring the plenum to sealing the heat exchanger, this video guide provides all the information you need for a successful installation. Don’t miss out on the tips and recommendations for a smooth process. Water to Air Heat Exchanger

Gathering Necessary Tools And Equipment

Before starting the water to air heat exchanger installation process, it is essential to gather all the necessary tools and equipment. This will ensure a smooth and efficient installation process. Here is a list of tools and equipment you will need:

- Measuring tape: This tool will help you accurately measure the dimensions of the plenum and the heat exchanger.

- Hacksaw or pipe cutter: A hacksaw or pipe cutter will be required to cut the necessary holes and pipes.

- Brackets: Brackets will be used to securely attach the heat exchanger to the plenum.

- Screws and screwdriver: Screws will be used to attach the brackets to the heat exchanger and the plenum.

- Sealant: A high-quality sealant is necessary to ensure there are no air leaks around the heat exchanger.

- Protective gloves and goggles: Safety should be a priority during any installation process. Protective gloves and goggles will provide the necessary protection.

Safety Protocols And Precautions

Prior to starting the installation, it is crucial to be aware of and follow the necessary safety protocols and precautions. Here are some important safety measures to keep in mind:

- Shut off the power: Before beginning any work on the furnace or the plenum, make sure to turn off the power to avoid any electrical accidents.

- Wear protective gear: Safety should always be a priority. Wear protective gloves and goggles to protect yourself from potential hazards.

- Work in a well-ventilated area: Ensure there is proper ventilation in the installation area to prevent the buildup of harmful gases.

- Follow manufacturer’s instructions: Every heat exchanger comes with specific installation instructions. Make sure to carefully read and follow them to ensure a safe and successful installation.

- Double-check all connections: Once the installation is complete, double-check all connections to ensure they are tight and secure. This will prevent any potential leaks or malfunctions.

By following these safety protocols and precautions, you can ensure a safe and successful water to air heat exchanger installation.

Step-by-step Installation Guide

Installing a water to air heat exchanger is an essential step in maximizing the efficiency of your heating and cooling system. Follow this step-by-step installation guide to ensure a smooth and successful installation process.

Mounting The Heat Exchanger Unit

- Start by determining the ideal location to mount the heat exchanger unit. Consider factors such as accessibility and airflow.

- Once you’ve found the perfect spot, securely mount the unit using appropriate brackets or straps.

- Ensure that the heat exchanger is level and properly aligned with the air and water systems.

Connecting To The Water And Air Systems

- Begin by identifying the water inlet and outlet connections on the heat exchanger unit.

- Connect the water supply line to the inlet and the return line to the outlet, ensuring a tight and leak-free connection.

- Next, locate the air intake and outtake points on your existing HVAC system.

- Connect the air supply line from the heat exchanger to the air intake point and the air return line from the heat exchanger to the outtake point.

Testing And Troubleshooting Initial Setup

- Before testing the system, ensure that all connections are secure and properly tightened.

- Turn on the water and air systems and monitor for any leaks or irregularities.

- If any issues are detected, troubleshoot the system by checking for loose connections or blockages.

- Make necessary adjustments and retest the system until it is functioning optimally.

Maintaining Your Heat Exchanger

Installing a water to air heat exchanger is made easy with simple installation steps. From cutting the plenum to sealing the heat exchanger, this guide covers everything you need to know for a successful installation.

Routine Inspection And Cleaning

Regular inspection and cleaning are crucial for maintaining the efficiency and longevity of your water to air heat exchanger. By performing routine maintenance, you can prevent potential issues and ensure optimal performance. Here are some steps you can follow to inspect and clean your heat exchanger:

- Start by turning off the power to the heat exchanger and allowing it to cool down.

- Inspect the heat exchanger for any signs of damage, such as corroded fins, worn-out gaskets, or leaks. Replace any damaged components as necessary.

- Next, remove any accumulated dirt, dust, or debris from the heat exchanger. You can use a soft brush or compressed air to gently clean the fins and tubes. Make sure to clean both the interior and exterior surfaces.

- Inspect the fans and ensure they are clean and functioning properly. Clean or replace any clogged or malfunctioning fans.

- Check the air filters and clean or replace them if necessary. Clogged air filters can restrict airflow and reduce the efficiency of the heat exchanger.

- Inspect the water-side of the heat exchanger for any mineral deposits or scaling. If you notice any build-up, you can flush the system with a descaling solution recommended by the manufacturer.

- Finally, once the heat exchanger is clean, you can reassemble any removed components and restore power to the system.

Identifying And Resolving Common Issues

Even with regular maintenance, it is possible for issues to arise with your water to air heat exchanger. By being proactive and addressing these problems, you can prevent them from escalating into more significant and costly repairs. Here are some common issues you may encounter and steps to resolve them:

- Inadequate heating or cooling: If your heat exchanger is not providing the desired temperature, check the thermostat settings and ensure they are set correctly. Additionally, inspect the air filters and clean or replace them if necessary. Restricted or clogged air filters can restrict airflow and affect the heating or cooling capacity of the system.

- Water leakage: If you notice water leaking from the heat exchanger, check for any loose connections or damaged fittings. Tighten any loose connections and replace any damaged parts. If the leakage persists, it is advisable to call a professional technician for assistance.

- Poor airflow: If you experience reduced airflow from the heat exchanger, check the fans and make sure they are clean and functioning properly. Clean or replace any clogged or malfunctioning fans. Additionally, check the ductwork for any blockages or obstructions that may be limiting airflow. Clear any blockages for improved airflow.

- Noise issues: If your heat exchanger is producing unusual noises, such as rattling or squealing, it may indicate a problem with the fans or loose components. Inspect the fans for any damage or loose blades. Tighten any loose components and lubricate any moving parts as recommended by the manufacturer.

By regularly inspecting, cleaning, and resolving common issues with your water to air heat exchanger, you can ensure its optimal performance and prolong its lifespan. Remember to always refer to the manufacturer’s guidelines and seek professional assistance if needed.

Frequently Asked Questions Of Water To Air Heat Exchanger Installation

How Do You Install An Air To Air Heat Exchanger?

To install an air to air heat exchanger, follow these steps: 1. Measure and cut the plenum of the forced air furnace. 2. Install the heat exchanger in the plenum. 3. Trim the plenum and seal the heat exchanger. 4. Determine the supply and return sides of the heat exchanger.

5. Avoid cutting only one hole in the plenum for a shelf. That’s it!

How Do You Size A Water-to-air Heat Exchanger?

To size a water-to-air heat exchanger, measure the dimensions of the forced air furnace plenum, choose the appropriate size heat exchanger, and install it securely using brackets. Considerations include the heating coil location and fan speed adjustment. Use proper tools and fittings, and ensure proper connections and sealing.

How Much Does It Cost To Install A Heat Exchanger?

The cost of installing a heat exchanger varies depending on factors like the size, type, and complexity of the installation. It is recommended to consult a professional HVAC technician for a specific quote.

Where Should Heat Exchanger Be Placed?

The heat exchanger should be placed in the plenum of the forced air furnace for easy installation and efficient heat transfer. Ensure proper sizing and use appropriate tools for attachment. Avoid cutting one hole in the plenum for a shelf.

Consider the location of the heating coil and adjust fan speed if needed.

Conclusion

Installing a water to air heat exchanger is a simple and efficient way to upgrade your heating system. With easy installation steps, such as measuring the plenum and sealing the heat exchanger, you can improve the performance of your forced air furnace.

By choosing the right size heat exchanger and using the proper tools, you can enjoy the benefits of a more efficient heating system. Upgrade your HVAC system in Austin, Texas, with a water to air heat exchanger installation.

I am a Water Heater specialist writer and blogger based in the USA & UK. I have been working with Water Heater for six long years. And I give trips on various Water Heater problems and solutions. I have a lot of experience with Water Heater And I share them here